Reed valves: other applications in race engines

In the previous article on valves, I turned to the subject of reed valves and their use in the induction section of a two-stroke engine. In race series where two-stroke engines are still popular, reed valves are commonly used and, owing to their mechanical simplicity, are likely to remain so. They require no mechanical drive or other actuation, and depend only on pressure differentials to open and close.

In the previous article on valves, I turned to the subject of reed valves and their use in the induction section of a two-stroke engine. In race series where two-stroke engines are still popular, reed valves are commonly used and, owing to their mechanical simplicity, are likely to remain so. They require no mechanical drive or other actuation, and depend only on pressure differentials to open and close.

There have been a number of uses of reed valves on four-stroke engines, some of which have been in the induction system, meeting with various degrees of success or lack of it.

UK-based Performance Bike magazine built a single-cylinder, four-stroke engine with a reed block in the intake some 20 years ago. The ethos of the machine was to provide something light and responsive. A new water-cooled head was commissioned from Silk Engineering in Derby, England, to fit on an existing engine, and the idea of the reed was to improve the engine's volumetric efficiency at speeds away from the 'tuned' speed of the engine by not allowing charge to escape back down the inlet.

However, the combined effect of having a large restriction in the inlet and something that so fundamentally affected the way the pressure waves behaved meant that the engine didn't behave as expected when it first ran. A lack of enthusiasm and money from the magazine consigned an interesting (but possibly technically doomed) project to the dustbin, and the whereabouts of the engine isn't known.

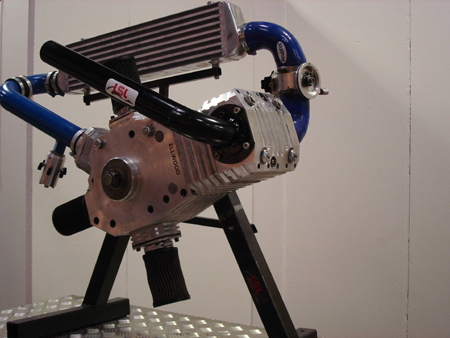

An interesting engine operating on similar principles is being developed by an enthusiastic engineer in Sweden, on very limited funds. The intake of the 'Ellwood Hybrid' 500 cc engine breathes via the crankcase, induction to which is controlled by reeds. As the piston descends, it compresses the charge in the crankcase and this is admitted to the long intake port using yet another reed.

There are, of course, two piston strokes that serve to compress the charge and so, while the intake valve is closed, there is a store of lightly compressed air trapped between the final reed valve and the conventional poppet intake valve. The engine, based on an old Godden speedway engine, has been run in a motorcycle and campaigned in circuit racing, drag racing and ice-speed record racing.

The original 500 cc version of the engine has been developed over 15 years, but a 1300 cc version is now also being built. The problem with this latter machine though is that the engine charge has to pass through an otherwise conventional four-stroke bottom end, replete with oil. The charge therefore 'picks up' a great deal of oil that is then carried through the rest of the inlet tract and into the combustion chamber, where it will be problem both for combustion and emissions.

The technology would perhaps benefit from using two-stroke oil in the bottom end, as the oil is designed with combustion in mind. However, in most two-stroke applications, the bottom end is essentially dry at start-up and oil is constantly metered to the crankcase, and is proportional to throttle opening. Simply using two-stroke oil in the crankcase in place of conventional lubricating oil would not solve the problem of excess oil in the mixture.

Readers wanting to see this novel engine in action can do so at the Swedish Landracing Speedweekend on Ice, 11-12 March 2011, where the 500 cc Hybrid will be running on nitromethanol.

Fig. 1 - The 'Ellwood Hybrid' 1300 cc engine, currently under development, uses reed valves in multiple locations in the inlet

Written by Wayne Ward