Honing pistons to perfection

When General Motors got out of the National Hot Rod Association's (NHRA) Pro Stock division a couple of years ago, it left behind a multitude of competitors using two of its engines in competition. The DRCE3 engine, newer than the DRCE2, has been the mainstay block-and-cylinder head combination for Warren Johnson Enterprises for the past five years.

When General Motors got out of the National Hot Rod Association's (NHRA) Pro Stock division a couple of years ago, it left behind a multitude of competitors using two of its engines in competition. The DRCE3 engine, newer than the DRCE2, has been the mainstay block-and-cylinder head combination for Warren Johnson Enterprises for the past five years.

Johnson himself, who with his son Kurt builds engines for their two-car operation, is known as 'The Professor' for his meticulous and methodical work patterns, as well as for his innovations in the category. He notes that, with the GM engines, "You've got block materials and significant inconsistency in the GM block. You look at the Ford and Mopar blocks, and you see a maximum of 12-thousandths cylinder wall change, where we have to live with stuff that is 200-thousandths cylinder wall thickness changes.

"Because of that cylinder wall change it becomes a real problem, and consequently piston skirt configuration becomes an area you need to address," Johnson advises. "You are constantly addressing skirt wear because of heat, rpm and loading from the different con rod and stroke combinations, so you're constantly changing skirt configuration and end up with, essentially, zero wear."

Over the years, he has changed his piston spec perhaps 14 times from the original box piston he designed in 1990. On a 500 cu in engine that runs about 11,000 rpm, Johnson has specified pistons from Wiseco Performance Products, based in Mentor, Ohio, for the past 15 years.

"They are the only manufacturer out there that does their own forgings and heat treating," he says. "Everything is done under one roof. The other manufacturers farm out our forging and heat treating so we prefer to deal with Wiseco..

"If you are going to have a change, it's nice to have it all performed under one roof. We can specify a forging and have our pistons in sometimes as little as a week-and-a-half, in the right circumstances."

Using a piston for as many as 35-50 passes down the quarter-mile racetrack, Johnson finds that he changes his piston specification as he adapts his cylinder head configuration. "The forging changes because we want a net piston that we don't have to go and do a lot of under-head lightening on," he says.

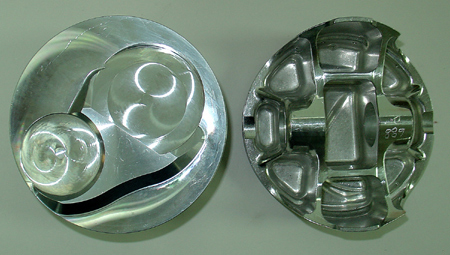

NHRA requires pistons to weigh a minimum of 460 g, so that under-head weight reduction of the piston weakens the structure of the piston. "We like a net forging that we can set up there in the engine, coming up with a piston that is relatively close to the weight minimum but still having a good service life," Johnson says. While he does not lighten the piston, Johnson's shop performs some additional machining to the gas ports and contours the piston dome to his exacting specifications.

"Thirty-five runs is easy, and even 50 runs too," Johnson says. "Some of the pistons still look good but we change them out for historical purposes. We don't throw anything away because we may have to use those pistons in an emergency."

Johnson uses the same engine configuration for 22 out of the NHRA's 23 races in the 2010 campaign. "We make small adjustments for Denver because of the lack of air there, but that's about it," he says.

Fig. 1 - Warren Johnson specifies his net piston from Wiseco Performance Products, and performs additional machining to the dome contour (Courtesy Warren Johnson Enterprises)

Written by Anne Proffit