Over a barrel

The increase in demand for specialist designer beers has led to a steady business in the supply of stainless steel barrels - or so we are told. Forsaking the traditional wooden barrel, which in the spirits and wines business is often known to add a characteristic flavour to its contents, these containers are very much utilitarian devices for transporting the contents from the brewer to the consumer with the minimum effort.

The increase in demand for specialist designer beers has led to a steady business in the supply of stainless steel barrels - or so we are told. Forsaking the traditional wooden barrel, which in the spirits and wines business is often known to add a characteristic flavour to its contents, these containers are very much utilitarian devices for transporting the contents from the brewer to the consumer with the minimum effort.

But unless you have tried to manoeuvre one of these 50 litre (11 gallon) devices either full or empty, you can't fully appreciate how easily they move. It's all in the shape, you see.

Similarly, another component conforming to a similar shape and one that may perhaps be of more interest to readers here, is the piston top ring. And rather like our ale cask, the barrel-shaped compression ring is the product of continuous development over many years.

The top ring in any piston assembly has the most arduous of tasks. Taking the full brunt of combustion events, it has to seal against an imperfect cylinder bore, coping with huge amounts of pressure variation and conducting large amounts of waste heat away from the piston crown while at the same time minimising any frictional losses.

Working in association with the rings beneath it, all this has to be done many times a minute and with losing the least amount of oil up into the combustion chamber. But as engine speeds get higher and rings thinner, and therefore required to be stronger, the need for the barrel shape has become even greater.

Ground or lapped into shape and then coated with any manner of favoured materials, once installed the ring offers virtually line contact all the way around the bore. And as the ring groove and ring invariably move or twist in response to the dynamic or thermal loads, this line contact will prevail when other profiles might lift in certain places and allow precious gas to escape.

In race engines, where engine life is always limited, bedding in of the ring against the liner needs to take place quickly, preferably in minutes, so as to not use up too much of that valuable running time. Even assuming the best of plateau hones, the narrow line of contact will produce high contact loads during initial running.

These loads will drop very quickly when the high spots on both the liner surface and ring are removed and the line of contact broadens. The big advantage of the barrel shape, however, is in the lubrication between ring and bore on both the upward and downward strokes.

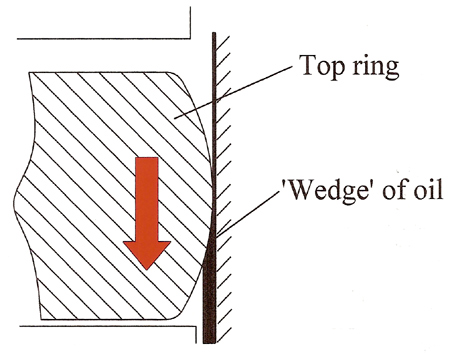

On the downward stroke, as the ring tries to strip away the oil left by the secondary, scraper ring, the shape of the barrel is such as to generate a 'wedge' of oil between the ring and the cylinder. The ring will ride over this very thin layer of oil, and hydrodynamic lubrication with minimal friction (and hence minimal wear) will result.

Likewise, on the upward stroke when the force between the ring and liner surface is not so great, since the high combustion pressures of the downward stroke are no longer forcing the ring outwards, the shape of the upper ring profile generates yet another wedge of oil and friction is minimised yet again. Even as the ring twists and turns through its dynamic movement, the geometry is such that on the upward or downward movement this wedge of oil is still present.

So, as in our cask of ale, a barrel shape has many advantages.

Fig. 1 - Top-ring lubrication

Written by John Coxon