Piston skirt coatings

The contribution of the piston assembly to overall engine frictional losses is well documented and has been the subject of a lot of research over a number of decades.

The contribution of the piston assembly to overall engine frictional losses is well documented and has been the subject of a lot of research over a number of decades.

In SAE paper 911230, for example, the authors Tsuchida and Tsuzuku study the effects of various design features on piston friction losses for high-speed engines (up to 16,000 rpm). At the time - the late 1980s and early '90s - the Japanese were selling production motorcycles with engine speeds higher than even Formula One engines were capable of revving to at that time. The first graph in their report showed that, for the high-speed engine being studied, crank and piston friction was by some margin the largest source of friction in the engine and transmission assembly.

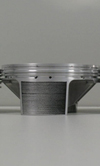

The reduction of piston assembly friction still remains a constant target of research projects in the mainstream automotive field. Coating pistons has been common in motorsport for many years, and the coating of piston skirts in particular has proven successful, with many companies offering these products. Such coatings found widespread success through many top-end race series including CART (Champ Car) and Formula One.

There are a few main types of piston skirt coating in general racing use; there are a number based on polymer formulations, with others based on graphite or a composite coating with a resin binder with fillers. The polymers are commonly spray coatings with a build-up of between 10 and 25 microns per surface (0.0004-0.001 in) and are based on PTFE, although screen printing methods provide for a more accurate method of application.

Sprayed coatings require masking to prevent overspray, according to Martin Keswick of Capricorn, who says that about 70% of the pistons Capricorn produces are coated. The polymer coatings are relatively soft, and piston manufacturers expect these to have significant loss of polymer in use, effectively wearing-in during use. This is a similar principle to that described by Yagi and Yamagata in SAE paper 820769, where they used a loaded resin composite coating as a way of rapidly determining optimum skirt profiles for automotive pistons.

The graphite coatings are applied by screen printing, and these are more durable than the polymer type. Graphite is a material renowned for its low friction.

The metallic-loaded resin coatings are specifically recommended to be run in hypereutectic bore materials.

A number of piston companies also phosphate pistons all over, giving them a grey colouration.

The reasons for coating a piston skirt are not necessarily to do with friction, but can be to combat wear and to make the piston less sensitive to skirt profile design in cases where the coating is expected to 'wear into' an optimum profile. The optimum skirt profile can be different for two seemingly identical engines, depending on how they are used, and the wearing polymer coatings means that we effectively have a piston surface that can adapt to the particular loads imposed on it.

The latest development, slowly trickling down to the wider racing market from Formula One, is DLC coating. This requires special piston machining and a special coating process so that the strength of the piston material is not compromised by the temperatures involved in the coating process.

Fig. 1 - This piston skirt is coated with a sprayed PTFE-based polymer (Courtesy of Capricorn)

Fig. 2 - All these pistons have run in engines. Some, such as the green PTFE coated item, show signs of wear, with others showing no obvious wear (Courtesy of Capricorn)

Written by Wayne Ward