Three into two will go

High lifts or long durations are common features in high-performance camshafts, and when optimised can produce high engine torques over a useful but often limited range of engine speeds. The introduction of variable valve timing can widen this range of useful speeds, but at part load against a partially closed throttle, large valve lifts introduce pumping inefficiencies that are increasingly unacceptable in performance roadcar engines. Over the past decade, therefore, a multitude of variable valve lift concepts for spark-ignition engines have evolved. The simplest of these is the so-called 'switching tappet'.

High lifts or long durations are common features in high-performance camshafts, and when optimised can produce high engine torques over a useful but often limited range of engine speeds. The introduction of variable valve timing can widen this range of useful speeds, but at part load against a partially closed throttle, large valve lifts introduce pumping inefficiencies that are increasingly unacceptable in performance roadcar engines. Over the past decade, therefore, a multitude of variable valve lift concepts for spark-ignition engines have evolved. The simplest of these is the so-called 'switching tappet'.

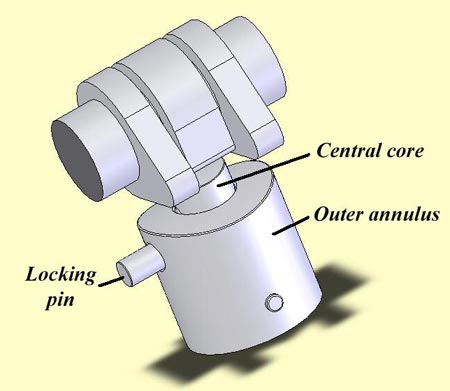

Invented by Lotus and manufactured under licence by INA Schaeffler KG in Germany, the tappet consists of an outer annulus surrounding a much smaller inner post, such that the mechanism can operate in two different valve lift modes. Taking the place of a traditional direct-acting mechanical bucket, the mechanism is operated by a system of three camshaft lobes per valve, which are packaged in the space previously occupied by only the one. The outer camshafts operate the outer annulus while the inner one, which has to be much lower in lift, acts on the inner central core.

This inner core and its outer annulus can move independently of each other until positively locked together by a spring-loaded plunger or locking pin operating under engine oil pressure. When the outer annulus and inner core are locked together, the outer cam profile is transferred to the valve motion. When unlocked, the central but lower lift cam will control the valve.

Since the oil pressure needs to be switched on and off to the tappet, two separate feeds are needed - one supplying the switching oil pressure (at about 1-1.2 bar pressure), the other supplying the lubrication. In addition to the normal valve spring(s) controlling the valve, the tappet has contained within it another, much lighter spring, ensuring that the outer tappet does not lose contact with the outer cams when the system is unlocked.

A relatively simple and surprisingly reliable component, often no bigger than the diameter of the standard tappet it replaces, in its unlocked mode the central tappet runs against the base circle of the inner cam, much as in a traditional hydraulic tappet. However, in the fully locked mode, the central tappet still runs on the base circle of the central cam until such time as the clearance between the base circle of the outer cam and that of the outer tappet is taken up. At this point the outer cam takes over to give the full valve lift, producing a sort of part-hydraulic, part-mechanical arrangement.

Generally running at much lower lifts - about 3-4 mm as opposed to, say, 9 or 10 mm of the main, outer cams - valves can be operated either in pairs or individually to control either tumble swirl or axial swirl depending on the in-cylinder air motion required. Furthermore, the inner cam can be advanced or retarded (using a variable cam-phasing mechanism) to enhance combustion stability, improve low-speed emissions or give better driveability around town.

A simple system in concept, switching tappets can be applied to many existing overhead-cam engines. Requiring few additional modifications to the cylinder head, correctly engineered they can produce high-performance engines with little in the way of compromise to everyday road use.

Fig. 1 - The switching tappet

Written by John Coxon