Ramping up

As an engineer first, a motorsport enthusiast second and historian third, I welcome the recent upsurge in historic rallying. But whereas most journalists or writers would perhaps reflect on the sheer thrill of hearing the sound of a BDA reverberating through the forests, my particular recollection is listening to one particular example idling just before entering a service halt. To put it bluntly, it sounded like a bag full of hammers!

As an engineer first, a motorsport enthusiast second and historian third, I welcome the recent upsurge in historic rallying. But whereas most journalists or writers would perhaps reflect on the sheer thrill of hearing the sound of a BDA reverberating through the forests, my particular recollection is listening to one particular example idling just before entering a service halt. To put it bluntly, it sounded like a bag full of hammers!

I'm used to listening to hot engines, and beneath the rhythmic pulsing of the intake and exhaust, piston slap is a familiar sound. But this particular noise coming from the tappet chest appeared to me at least to be all camshaft-related. Indeed, it sounded very much as if the camshaft profiles were missing one very important parameter - the opening or closing ramps!

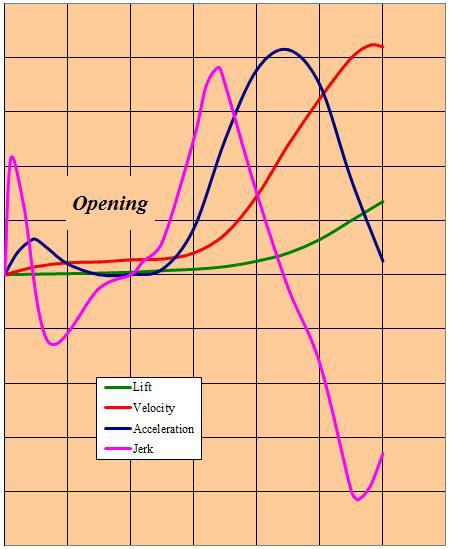

A normal camshaft valve-opening profile consists of three stages. The first consists of lifting the valve gracefully off its seat before rapidly accelerating it open in the second stage and then slowing it down again for the third, when it is fully open. Interrelated, the general idea is to open the valve as quickly as possible and benefit from what is called 'maximising the airflow under the curve' - and, apart from ensuring that the spring and camshaft material can cope, other concerns are principally valvetrain dynamic issues and of course, in road transport applications at least, the noise. But while some noise can be generated from the vibration of the valve springs, much of it comes from the contact at the initial lifting of the valve off its seat and placing back thereupon again.

Traditional practice in the design of the ramp is to specify a constant velocity which ensures that the valve is picked up at a known speed once the initial tappet clearance, in the case of mechanical tappets, is taken up. For hydraulic tappets the amount of sink-down has to be taken into account. On the closing side, the seating velocity is critical, particularly to the durability of the exhaust valve when at higher temperatures material properties may suffer.

The height of the ramp therefore has to be enough to ensure seating once differential thermal expansion, base circle run-out, valve cock and - in the case of hydraulic tappets - other sink-down effects have been taken into account. For mechanical tappets this ramp height may be 0.3-0.45 mm for both opening and closing, with a ramp rate, a preference of the designer depending on the application, of somewhere around 0.015-0.030 mm/degree not being uncommon. In some cases, since seating velocity may be critical, the closing ramp rate may be slightly less than that of the inlet allowing the valve to seat carefully without the risk of bounce.

But in the search for more engine performance it may be necessary to open the valve much quicker, and if that is the case then a number of options are available. The first option, and the one most often exploited by engine tuners the world over, is to reduce the tappet clearance progressively until the power falls away. This has the effect of increasing the area of possible airflow underneath the curve with no additional stress into the valvetrain. However, although peak valve opening positions relative to top dead centre will not change, the optimum cam position may do so but only slightly.

Shorter constant-velocity ramps might also help, but assuming the valvetrain has been designed carefully, these will be no longer than required anyway. The only other way is to pick up the valve at a higher velocity using some kind of constant acceleration ramp rather than one of constant velocity. Although the impact force will be much greater, and consequently durability much less, as soon as the valve leaves its seat it will be accelerating much faster than before, hence in effect opening sooner. A challenge to the designer and presumably very difficult to manufacturer, it might also sound almost as bad as my bag of hammers.

Fig. 1 - The opening ramp of a typical valve profile

Written by John Coxon