White-metal magic

Still considered by many to be some of the best materials around, white bearings are still commonly used in many vintage racers. This is not, as you might suppose, as a result of just the friction qualities of the material alone, but more as a consequence of its 'embeddability' (the ability to absorb dirt into its surface) and its nature to yield under excessive local pressures - as a result of, say, shaft misalignment - which prevents seizing.

Still considered by many to be some of the best materials around, white bearings are still commonly used in many vintage racers. This is not, as you might suppose, as a result of just the friction qualities of the material alone, but more as a consequence of its 'embeddability' (the ability to absorb dirt into its surface) and its nature to yield under excessive local pressures - as a result of, say, shaft misalignment - which prevents seizing.

In a properly designed bearing, the oil forms a thin film between the journal and the bearing, and separates the two such that no contact should take place so friction is therefore minimal. Only during stopping and starting, when boundary lubrication is present, is friction high and the bearing ever at risk, or if highly flexible cranks are used when the bearing is loaded at its edge.

So the 'slipperiness' of the bearing material is not the main issue. More particularly, it is the strength of the material, its ability to absorb the loads placed upon it, and the ability to cope with the heat that may result. Ideally, and often forgotten, a good bearing material should also be able to fail without damaging the journal that runs within it. In this way, costly crankshafts can be saved at the expense of much cheaper bearing components. As load factors increase with engine performance, this last factor becomes harder to achieve.

In the case of white metal, the options are generally either lead-based or tin-based. The stronger of these are the tin-based bearings, which will not only accept much higher loads but much higher surface speeds as well. Known as Babbitt metals - not to be confused with lead-based alloys which are often erroneously referred to also as Babbitt metals - these are typically 80-90% tin (Sn) mixed with 8-12% antimony (Sb) and about 3-6% copper (Cu). When dissolved in the tin, the antimony forms a eutectic of very hard crystals of SnSb which, being lighter than the melted mixture, will ordinarily float to the surface to give a hard, upper layer on top of a relatively soft, lower one.

The material in this state would be too hard at the top and too soft underneath for satisfactory bearing applications. The addition of copper to the melt upon cooling produces dendrites of Cu6Sn5, which interlock, preventing the free movement of the hard SnSb constituent and producing a more consistent material, more easily used by the bearing casting industry. A bearing produced in this way gives a more uniform distribution of hard load-bearing particles within a soft malleable matrix with a much lower melting point. So, as the bearing wears, the softer metal erodes to create a refuge for the lubricant, while the harder interstitial particles provide the actual bearing surface.

When considering the elemental composition it is important to remember the effect of lead. In times past the manufacturing method for making tin invariably included an unavoidable impurity of up to 0.35% lead (Pb). When introduced into a tin-antimony mixture, this impurity surrounds the SnSb crystals and weakens the microstructure. Forming yet another eutectic with tin and antimony, the lead reduces the melting point of one component to 143 C, which is only slightly above that of the bearing's normal operating temperature and is clearly unacceptable for any form of competition. When supplying tin-antimony bearings for competition use, only the purest form of tin, free of lead, should therefore be used.

To many, white-metal, Babbitt bearings may be considered old-fashioned or even slightly downmarket. However, in their more modern, much purer form they can be superior and more accommodating to more modern bearing materials when used against older type and more flexible cranks.

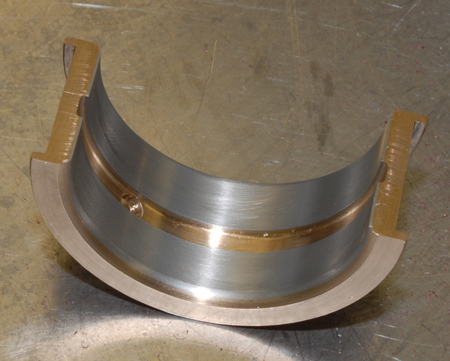

Fig. 1 - Fully machined white-metal bearing ready for installation

Written by John Coxon