Time for a change

In these times of political and economic upheavals around the world it seems there is an appetite for change in other areas of life as well. Suggestions for a revamp to the Formula One engine regulations could fill a whole book but it is the latest - including direct injection or gas turbine technology - that have really hit the headlines recently.

In these times of political and economic upheavals around the world it seems there is an appetite for change in other areas of life as well. Suggestions for a revamp to the Formula One engine regulations could fill a whole book but it is the latest - including direct injection or gas turbine technology - that have really hit the headlines recently.

For those with long memories, gas turbines were all the rage in the late 1960s and early '70s. Undeterred by the experiences of the Rover BRM project of 1962-65, the Howmet GT, STP-Paxton and the Lotus 56 all used gas turbines to various effect, and all were controversial to some degree.

At the time, the automotive industry was looking to the gas turbine as the next Big Thing, but when hopes of fuel efficiency comparable with the reciprocating engines of the period petered out, interest steadily waned. But at a time when fuel efficiency is everything, one wonders why gas turbines in Formula One have been mentioned at all?

On the other hand, the inclusion - or rather, non-exclusion - of direct injection is surely only common sense. I always found it strange that direct injection was banned in Formula One some years ago on the grounds of spiralling engine development costs. Yet it is arguable that DISI (direct injection spark ignition) is the one area where the resources of the manufacturers could have been most successfully applied.

Nowadays, just about every vehicle manufacturer has or is about to introduce a spark-ignition, direct-injected unit, and if Formula One is to resume its place at the pinnacle of engine technology then turbocharged or naturally aspirated, heat-recovered or KERS direct injected is surely an absolute must.

Although the in-cylinder motion and position of the injector are different from those in a port-injected device, from the ECU's standpoint there is little change. The ignition system is still the same, and although the fuel has to be injected in a much shorter time frame (helped by the 200 bar fuel pressure), any high-level engine management system should be more than capable, at least in homogenous combustion mode. For more complex, fuel-saving modes multiple injections per cycle may be necessary.

So for the most part there is little change required at the ECU but one major change, as explained to me recently, was in the problems associated with the gear change.

In a port-injected engine, during the gear change both fuel and spark are cut momentarily and then reinstated according to any number of user-developed algorithms. During this process the manifold and inlet port wall wetted by the fuel in earlier cycles progressively dries out during the non-fuelled cycles and then adsorbs some of the fuel when reinstated.

Despite the best efforts by engineers to compensate for it, this 'imperfect' fuel-air mixture reduces the shock loading and introduces a level of 'cushioning' to the transmission. In direct injection, when the fuel is metered directly into the cylinder, this drying out and re-wetting doesn't take place, and even taking into account any 'ignition cycle recovery' caused by the lack of residual gas in the chamber - and without any change to the fuelling on re-instatement - the extra shock loading introduced could have a major impact on the durability of the drivetrain.

Since gearboxes are expected to last for at least four races, any move towards direct injection will need to address this issue - as well, no doubt, as many more.

So, gas turbines? Regretfully, no. But direct injection? Definitely yes! Yet surely that goes without saying.

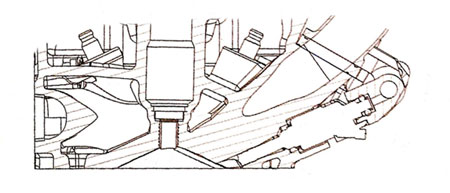

Fig. 1 - Direct injection, surely the future in Formula One?

Written by John Coxon