Timing is the key

The design of valve lift profiles can no longer be described as the sole province of the specialist engineer. Today we have many excellent software packages that will do just that without having to go anywhere near a polynominal equation or even think about things like 'instantaneous radii of action'. Introduced to the precise geometry of the valvetrain, these will, with relative ease, output a profile within the constraints of jerk, acceleration and velocity. Once more, with the interactive nature of these programmes, all this can be achieved in a matter of hours rather than

The design of valve lift profiles can no longer be described as the sole province of the specialist engineer. Today we have many excellent software packages that will do just that without having to go anywhere near a polynominal equation or even think about things like 'instantaneous radii of action'. Introduced to the precise geometry of the valvetrain, these will, with relative ease, output a profile within the constraints of jerk, acceleration and velocity. Once more, with the interactive nature of these programmes, all this can be achieved in a matter of hours rather than

weeks (or even months) using a calculator and pencil and paper.

But in all this we must not forget that the camshaft is only the switching element of a valve feeding intake gas to the engine and enabling extraction of the spent gas thereafter. Assuming our mechanism can flow sufficiently to fill the cylinder in the time required, the next significant requirement is the timing of these opening and closing events.

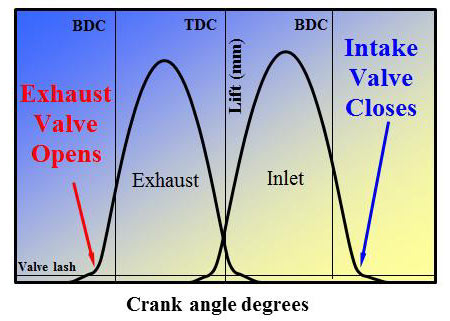

That we are trying to open and close the valves in the shortest possible time must surely go without saying. But in order to do so and gain maximum benefit, these actions have to be instigated at times that to some might make little sense - for instance, the opening of the exhaust valve.

Once the fuel-air charge is burning, the pressure in the cylinder will reach a maximum sometime shortly after TDC (top dead centre). After a further 90º or so of crank rotation, most of the energy has been recovered in terms of mechanical torque on the crankshaft, so opening the exhaust valve well before BDC (bottom dead centre) loses little in actual performance.

The period after exhaust valve opening (EVO) is generally referred to as 'blowdown', and although irrecoverable in terms of energy lost, the extraction effect in the exhaust can assist in reducing the pumping losses that would otherwise be incurred in pushing the exhaust gases out on the piston upstroke. Perhaps the least significant of all cam timing events, EVO generally occurs between 50º and 90º BBDC (before bottom dead centre).

If EVO is considered the least important then, of the four intake/exhaust events in the four-stroke cycle, the intake valve closing position is arguably the most important. Intake system dynamic events tend to dominate the characteristics of any naturally aspirated four-stroke engine. In many past discussions on this subject the unsteady flow in the intake system was considered to be the algebraic sum of two phenomena - wave ram and inertial or column ram.

At the time, column ram was considered to be simply the inertia of a column of air flowing down the intake runner, onto which would be superimposed the oscillating pressure pulses resulting from the combined effects of valve opening and piston movement. As a result of much analysis - and as I was continually reminded by the late Prof Gordon Blair - this is not now considered to be the case, and only the pressure pulses travelling up and down the intake system need to be considered.

Thus the wave ram negative pressure pulses produced as the intake valve opens travel up the runner and are reflected back as a positive wave. As this wave reaches the intake valve again, if the valve is on the point of closing, the slight increase in pressure will improve the volumetric efficiency of the cylinder by trapping that little bit of extra air. Should it arrive back a little later as a negative pulse then the reverse is true and the volumetric efficiency will fall. Ensuring that the intake valve closes at the most beneficial time is therefore the secret to good performance.

So while getting the valve open (and closed) in the shortest possible time is important, ensuring this happens at the correct point in the cycle is perhaps more so.

Fig. 1 - Valve events on the four-stroke cycle

Written by John Coxon