Wet sumps

Though rare in most competition cars, wet sumps are still found in race series as diverse as touring cars and drag racers. Each of these places different demands on the lubrication system, with engineers trying to strike a balance between ensuring sufficient oil supply without increasing the losses due to 'windage' effects (the parasitic losses caused by friction between the oil and rotating components). Here I want to investigate some of the methods used by drag racers to circumvent the problems inherent in wet sump oil systems.

Though rare in most competition cars, wet sumps are still found in race series as diverse as touring cars and drag racers. Each of these places different demands on the lubrication system, with engineers trying to strike a balance between ensuring sufficient oil supply without increasing the losses due to 'windage' effects (the parasitic losses caused by friction between the oil and rotating components). Here I want to investigate some of the methods used by drag racers to circumvent the problems inherent in wet sump oil systems.

Some drag racing classes require the use of wet sump oiling systems, while some competitors prefer the simplicity of not running a dry sump. Interestingly, the problems that often arise in relation to ensuring sufficient oil supply are not always where one would initially expect to find them. Clearly the forces exerted on the oil under hard launches are considerable, but ensuring sufficient pick-up is usually simply a case of locating the oil pick-up at the rear of the sump, eliminating the possibility of starvation.

It is in fact under braking that problems can arise, with users of wet sumps often suffering a considerable drop in oil pressure during braking at the end of a run or after the burnout. One solution was for drivers to kill the motor as they crossed the line, before braking or deploying the parachute, in addition to gradually slowing down after burnouts. However, neither approach is ideal and racers have been looking at better ways of controlling the oil within the sump.

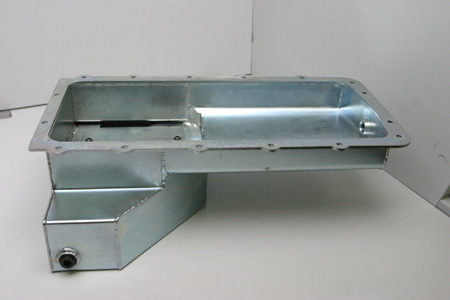

There are number of approaches here. The starting point for improving the oil supply is by increasing the capacity of the sump. Due to issues with ground clearance and engine height, this is often achieve by designing extra horizontal capacity, often called 'kick-outs'. Increasing the capacity is a good start, but better control of the oil's movement is the real solution.

One of the oldest methods is to use a horizontal baffle across the sump, with a series of one-way trapdoors, the purpose being to allow oil to flow to the pick-up under launch but restrict its flow forwards during braking. The key disadvantage with this type of design is the time it takes for the trapdoors to close as the oil tries to move back along the sump, with significant quantities of fluid transferring before the traps are shut.

One solution by manufacturers of drag racing sumps is to replace the trapdoor system with a series of ball valves. These respond much faster than trapdoors, and extensive track testing has shown that they considerably reduce the volume of oil slosh. While baffles and check valves can aid oil control, careful design of the sump shape is also important to ensure that their function is optimised. Sumps will often have a stepped profile, with a deeper section at the rear to ensure there is always enough oil at the pick-up.

As mentioned earlier, ensuring a reliable oil supply is not the only important factor. In many drag racing classes, competitors are separated by hundredths of a second at the finish line, so any horsepower gain at the wheels - no matter how small - can prove decisive.

Power loss due to windage can be significant, especially in large-capacity V8s, which have very big reciprocating components. Windage plates or screens have long been a popular solution here. These take many forms but all try to reduce the potential for oil to splash from the sump onto the crankshaft. There is, however, some debate as to how effective windage plates are, with some manufacturers feeling that they actually increase parasitic losses if they're not properly designed, due to the restriction of oil return to the sump.

Another approach to reducing the effects of windage is the use of oil scrapers, positioned close to the crankshaft, which remove excess oil attached to the crank webs.

Although the wet sump may be a rarity in modern racing, competitors who use them are still pushing their development to try to circumvent the inherent disadvantages of this type of oil set-up.

Fig. 1 - A custom-built sump for a V8 drag engine. Note the substantial 'kick-out' at the rear of the sump and the integral baffle plate in the shallower section

Written by Lawrence Butcher