Hollow camshafts

Isn’t it always the case that when you think you have designed the best cam profile ever – at least in your opinion – somebody always wants it smaller, lighter and/or even cheaper to manufacture? Is it little wonder then that when everybody else is looking at magnesium cylinder blocks, metal composite con rods or ceramic valvetrain parts, the camshaft designer is looking to save, what, a few grammes?

The problem with the camshaft is that other than tinker with the profile you can seemingly do very little with it. Sure, you can drill a hole down the centre and take out a little weight, and even spark-erode some of the zone between the base circle and the cam lobe. I have even heard of Formula One teams designing ceramic, net-shape lobes (for they would need to be) and assembling them on steel tubes, but these were prototypes (and unsuccessful ones, I am told) and never made the light of day. Not too long ago, people were even talking about disposing with the camshaft altogether, preferring to replace it by electrically operated solenoids, and when that didn’t come to fruition, they moved on to using hydraulics to operate the valves. Over time, however, many of these schemes have been abandoned, which is why the vast majority of valvetrains around the world are still mechanical in nature.

But the camshaft as we know it seems to be here for a while longer, and therefore ways of improving it would seem to be the only game in town. Inevitably one of these ways is to reduce the weight.

Hollow cams are of course nothing new. Used purely for saving weight, any reduction in rotating inertia can only be marginal – first because the material is taken from the centre of the cam, where the rotational inertia of the cam is least effective, and second, when running at half that of crankshaft speed, the inertia of the cam, when referred back to the crank, is less in any case. The inertia of a shaft through a gear system is inversely proportional to the square of the speed ratio, so whatever reduction in inertia is made to the cam is proportionately less than the square of the speed ratio when transposed to the engine output shaft and hence the flywheel. So if the saving in inertia is only marginal anyway then the only benefit of hollow cams is principally down to the reduction in engine weight – which of course is always worth having.

And while some cams can be cast hollow, others can undergo somewhat expensive and quite difficult gun drilling operations. But once drilled they can be used to feed oil down to individual bearings or perhaps even the cam phaser on a VVT system.

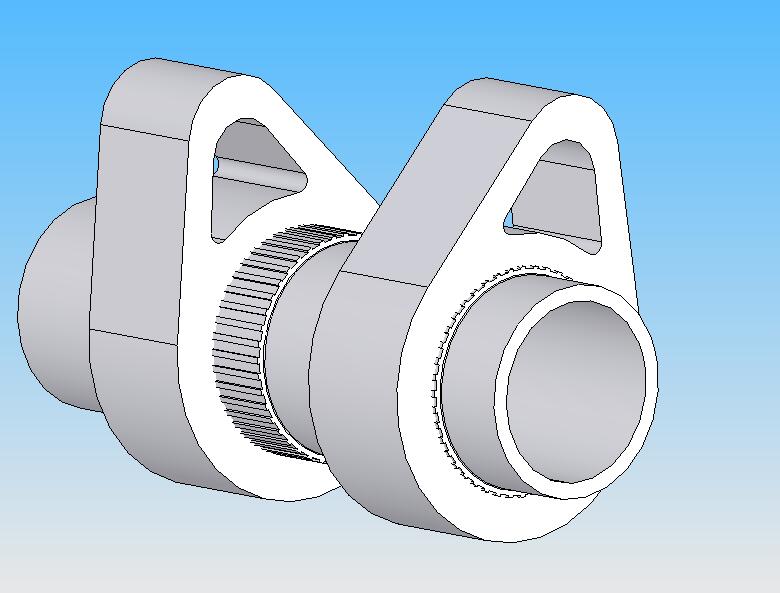

Another alternative that is steadily gaining converts in the original equipment world is the ‘assembled camshaft’. Consisting of a hollow steel tube with forged or sintered cam lobes positioned on it, the tube is expanded either hydraulically or by passing a carefully sized mandrel down the centre, and through it thereby anchoring them. Simple, if not easy to do in practice, this is surely only for manufacturing in volume.

But for those with deep pockets but who face restrictions on what they can and can’t do, camshafts for Formula One are simply machined from solid from the finest of steels. Rather better than even aircraft-quality steels, these have minimal inclusions that enable the tubular portion of the shaft to be machined to a minimum of 1.5 mm thick.

High strength? Certainly. Light in weight? You bet. But cheap? I’ll let you decide.

Fig. 1 - CAD rendition of an assembled camshaft

Fig. 1 - CAD rendition of an assembled camshaft

Written by John Coxon