MotoGP transmissions

The latest transmission development in the top flight of motorcycle racing, MotoGP, has been the appearance of seamless shift technology. Already commonplace in Formula One, seamless shifting provides a number of benefits to the rider and, more important, helps reduce lap times.

The latest transmission development in the top flight of motorcycle racing, MotoGP, has been the appearance of seamless shift technology. Already commonplace in Formula One, seamless shifting provides a number of benefits to the rider and, more important, helps reduce lap times.

Honda is currently the only team on the grid to admit to using a system, and it certainly made an impact on its debut at the Sepang pre-season tests in 2011. Honda Racing's Shuhei Nakamoto said at the time, "Obviously HRC is not using anything illegal, but it's true that we have something new on the transmission that currently allows for faster gear changes."

Seamless shifting as such is not unique in motorcycle transmissions, with Honda having developed a dual-clutch transmission (DCT) system for its larger-capacity consumer bikes. However, by its very nature, a DCT system is large and bulky, exactly the opposite of what is needed in a GP bike, as any performance gains would be offset by added weight.

A system similar to those found in Formula One would also not be as appealing. While a subject in its own right, essentially Formula One seamless shifts engage two gears at once, giving about a 4 ms window to disengage one or other gear, before the box destroys itself! High-pressure hydraulic systems are used to ensure that the first gear can be disengaged, preventing this happening. This is not an attractive proposition on a GP bike, because of the packaging requirements of the hydraulics and the possibility of locking the wheel if the system fails.

There are several motorcycle seamless shift systems available, but the GP teams are keeping tight-lipped about whose technology they are using. Two British companies, Xtrac and Zeroshift, produce the technology, but neither is willing to confirm their involvement with a particular team. Zeroshift though was willing to explain the workings of its system.

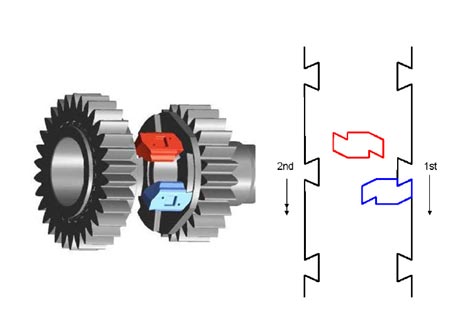

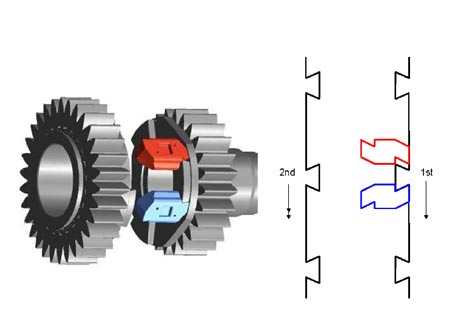

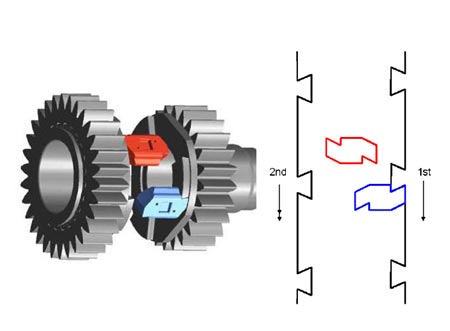

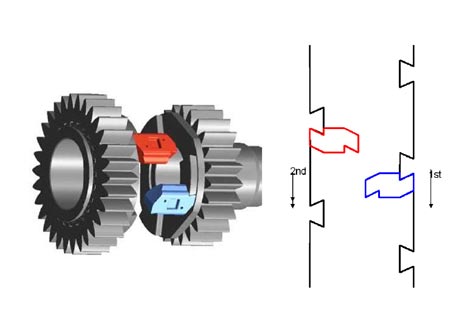

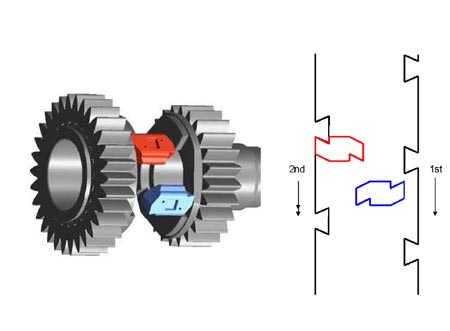

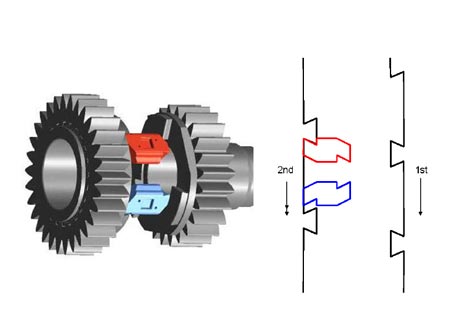

In a regular bike gearbox, the selection of the gears is still achieved by a sliding dog ring, which spins freely between shifts. The Zeroshift transmission eliminates the dog rings, and instead uses 'bullet rings' to engage the gears. A gear is selected when one ring is moved until its bullets hook onto drive teeth on the side of that gear. A second bullet ring moves in the same direction, with its bullets filling the gap between the teeth, eliminating any slack between the gears. Eliminating this slack is what creates seamless upshifts and downshifts. The shift sequence is illustrated below.

Fig. 1 - The Zeroshift system eliminates the gear dogs found in a standard racing transmission, replacing them with shifter 'bullets'

Fig. 2 - Neutral selected, with first gear about to be engaged

Fig. 3 - All three bullet teeth then mesh with first gear

Fig. 4 - Drive is maintained to first gear as the bullet starts to move in readiness for the second gear

Fig. 5 - The second gear ring is now engaged, but drive continues to be transferred to first gear

Fig. 6 - Second gear fully engaged with first gear bullet now merging into second gear ring

Fig. 7 - First gear has been fully disengaged, with second gear now transmitting all the power

This not only gives faster shift times, it also presents the rider with a far more stable platform under shifting. With a seamless transmission of power, it is even feasible to upshift in corners in adverse conditions, something that would be guaranteed to throw you off if attempted with a regular quick-shift system.

The system could also have a place in the long-term future of bike racing, notably if GP bikes were ever to become fully electric. Zeroshift has put considerable work into developing the system for use with electric vehicles and hybrids.

To date, nearly all electric vehicles have used a direct drive system, but the space limitations within a motorcycle frame limit factors such as motor and battery size. It is here that a transmission system can give an electric motorcycle greater flexibility by better using the motor's torque. While the days of all-electric racing are probably still a long way off, it is solutions like this that will help make it truly feasible.

Written by Lawrence Butcher