NASCAR and the gearbox of tomorrow

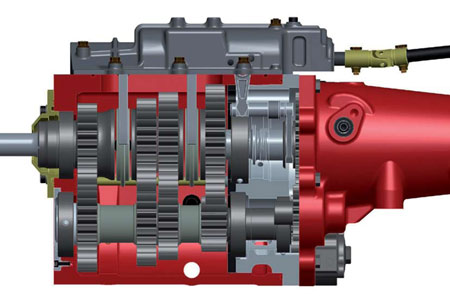

It is hard to imagine that a current-generation racecar, in a leading race series, owes its gearbox design to a unit that first appeared in a roadcar in 1957. However, this is the case in NASCAR Cup, where the only approved gearbox designs still have to resemble the venerable Borg Warner ST10, first used by General Motors in the 1950s. The external appearance is where the similarity ends though, with the internals, provided by a number of manufacturers, bringing the design right up to date. This article will look at some of the areas where improvements are still being made in the COT drivetrain, despite the restrictive nature of the NASCAR rulebook.

It is hard to imagine that a current-generation racecar, in a leading race series, owes its gearbox design to a unit that first appeared in a roadcar in 1957. However, this is the case in NASCAR Cup, where the only approved gearbox designs still have to resemble the venerable Borg Warner ST10, first used by General Motors in the 1950s. The external appearance is where the similarity ends though, with the internals, provided by a number of manufacturers, bringing the design right up to date. This article will look at some of the areas where improvements are still being made in the COT drivetrain, despite the restrictive nature of the NASCAR rulebook.

In terms of the gearbox itself, the main advances made by manufacturers have centred on reducing frictional losses. With the various engine offerings all falling within a few horsepower, even a small percentage reduction in power loss can prove decisive, especially on tracks where restrictor plates are mandatory. Surface finishing techniques have played a major role in these frictional reductions, with all the transmission manufacturers using either a media or chemical-based finish on components such as gears and shafts.

Chemical processes are gaining greater favour, thanks to their ability to improve the material characteristics of a component as opposed to simply smoothing its surface. Not only does this attention to finishing reduce friction between the gears, it also increases their durability. Combined with an increasing trend towards ground as opposed to milled gear sets, this has meant that the meshing between gears at a microscopic level has improved. This in turn has allowed engineers to reduce the size of the gears, further reducing parasitic losses through a decrease in rotating mass. One manufacturer has even gone so far as to add scallops to the gear face to remove yet more mass.

The gearbox is not the only area that has seen improvements, with the ring and pinion being the subject of considerable development by teams and parts suppliers to improve both performance and reliability. For many years, teams would use an off-the-shelf, machine-cut ring and pinion gear which was less than optimal in terms of performance and subsequently treated as a disposable item after only a few races.

One manufacturer though has bucked this trend by producing a bespoke item, featuring the latest advances in gear manufacturing technology. A key factor that enabled the company to make considerable gains in performance was access to advanced gear design software, which allowed engineers to optimise the profile of the gear teeth for maximum efficiency. This design capability, combined with the use of a proprietary steel formula and features such as gun drilling of the pinion shaft, has resulted in a ring and pinion that is lighter and more durable than anything currently available.

In practice, the new components can comfortably be used for ten-plus races without any reduction in performance, whereas the old gears would be replaced after only three. However, crew chiefs are still unwilling to run them for their proven usable life, so have been replacing them after five or six races. This led the manufacturer to reassess the gear design: if the gears were going to be used for only five races, there was no need to overbuild them. The result was a new, revised version of the ring and pinion, with a shorter service life but even greater efficiency gains.

This is only a brief glimpse of the work being undertaken to improve what is essentially a 1950s-vintage driveline. But rest assured, although its roots may be in the past, the modern NASCAR transmission is not short on cutting-edge technology.

Fig. 1 - A current-generation four-speed NASCAR Cup gearbox

Written by Lawrence Butcher